Vibrating Fork Level Switch

Vibrating Fork Level Switch Specification

- Number of Module

- Single

- Automation Grade

- Automatic

- Max. Current

- 5A

- Rated Voltage

- 220V AC

- Response Time

- <1 sec

- Protection Level

- IP66/67

- Circuit Type

- SPDT Relay Output

- Finish Type

- Polished Stainless Steel

- Mechanical Life

- >1,000,000 cycles

- Product Type

- Vibrating Fork Level Switch

- Material

- Stainless Steel (SS316)

- Insulation Resistance

- 100M at 500V DC

- Contact Resistance

- 100m

- Max. Voltage

- 250V AC

- Stoke

- Fixed (Fork length: approx. 100mm)

- Size

- Approx. 100mm fork length, flange mount

- Color

- Metallic

- Weight

- Approx. 1.2 kg

- Mounting Type

- Flanged/Threaded

- Current Rating

- 5A max

- No Of Poles

- Single

About Vibrating Fork Level Switch

We have been serving our respected clients since 1996 by manufacturing and supplying excellent quality Vibrating Fork Level Switch. It is well engineered and fabricated at our state-of-the-art facility using quality tested materials and cutting edge techniques. This switch is widely used for regulating the flow of corrosive, thick, turbulent, and flowing liquids. It has no moving parts and has stainless steel coated probes. Moreover, it generates less noise and vibrations during operations. All these qualities make this Vibrating Fork Level Switch highly demanded in the market. Also, these switches are properly checked on well-defined parameters prior to final delivery.

Vibrating Fork Level Switch

FEATURES ::

- No moving parts

- Self-cleaning for most media

- High immunity against vibrations

- Stainless steel and ECTFE coated probes

- Solid rod extension up to 3 m

- Various output configurations

- Selectable density

- High or low fail-safe mode

- Plastic, aluminium or stainless steel housing

- Explosion-proof models

- Most liquids with max. 10,000 mm2/s viscosity

- Corrosive, thick, turbulent, flowing liquids

- Granular material and powder with min. 0.05 kg/dm3 bulk density

- Power supply: 20-255V AC, 20-60V DC

- Ambient temperature: -40 C to +70 C

- Medium temperature: -40 C to +130 C

- Pressure: max. 40 bar

- Process connection: 1, 11/2 or flanges or hygienic fittings

- Output: 1 or 2 SPDT relays, 2-wire AC or DC, transistor (PNP, NPN)

- Protection: IP 67, IP 68

- Approvals: II 1/2 D IP6x T160C

- II 1 G EEx ia IIC T6...T4

- Germanische Lloyd

Advanced Sensing Technology

Utilizing vibrating fork technology, this level switch enables precise and reliable material level detection. The automatic operation and fast response time (under 1 second) make it a preferred choice for industrial applications where uninterrupted monitoring is crucial.

Durability in Harsh Environments

Built with SS316 stainless steel and offering IP66/67 protection, the switch can withstand corrosive and wet conditions. Its mechanical life surpasses 1,000,000 cycles, assuring longevity and minimal maintenance, which is vital for continuous industrial operations.

Flexible Installation and Application

The flanged or threaded mounting options allow for seamless integration into various tank designs. Its compatibility with multiple connection types and a polished metallic finish contribute to both functionality and aesthetic value, meeting the needs of distributors, exporters, and suppliers alike.

FAQs of Vibrating Fork Level Switch:

Q: How is the Vibrating Fork Level Switch installed in a tank or silo?

A: The switch is designed for easy installation using either flanged or threaded mounting options, ensuring secure integration into most standard tanks and silos.Q: What materials is the Vibrating Fork Level Switch suitable for detecting?

A: It is ideal for detecting the level of liquids or granular materials, providing accurate results for applications in water, oils, chemicals, grains, or powders.Q: When should the Vibrating Fork Level Switch be used in an industrial process?

A: Deploy the level switch when precise, automated level measurement is needed to prevent overflow, dry running, or maintain process continuity in tanks and silos.Q: Where can the Vibrating Fork Level Switch be applied?

A: The switch is suitable for use in chemical plants, food processing facilities, water treatment stations, and storage tanks where reliable level control is essential.Q: What benefits does the IP66/67 protection level offer?

A: The IP66/67 rating protects the switch from dust and strong water jets or immersion, ensuring dependable performance in harsh and demanding environments.Q: How does the switchs automation grade and fast response time improve efficiency?

A: With automatic operation and a response time under one second, the switch immediately detects level changes, helping operators quickly address process variations and minimize downtime.Q: What is the process for maintaining the Vibrating Fork Level Switch over its lifetime?

A: Routine visual inspections and occasional cleaning are sufficient due to its polished SS316 finish and high mechanical life, resulting in low maintenance and reliable operation throughout its lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Switch Category

Level switch - Top / Side mounted Type

Minimum Order Quantity : 1 Box

Material : Stainless Steel / Polypropylene (PP) / Brass

Max. Current : 1A / 5A

Max. Voltage : 250V AC/DC

Automation Grade : Automatic

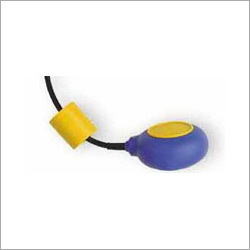

Cable Float Level Switch

Price 1500 INR / Box

Minimum Order Quantity : 1 Box

Material : PPS

Max. Current : 10 Ampere (amp)

Max. Voltage : 250 AC Volt (V)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry